In alignment with India's National Policy on Biofuels - 2018, we recognize the escalating thrust towards biofuel utilization, especially within the energy and transportation spheres. Our commitment to contribute to the ambitious target of producing 15 Million Metric Tonnes (MMT) of Compressed Biogas (CBG) by 2030 underpins this article. In this introductory section, we shall guide you through the intricate process of establishing your own CBG plant, shedding light on pivotal aspects such as CBG plant setup requirements, site selection, acquisition of the necessary license for a CBG plant, and the nitty-gritty of design and construction.

We understand the complexity of managing the feedstock supply for a Gobar Gas Plant and the intricacies of the CBG plant setup process, which is why we delve into the operational mechanisms with meticulous attention to detail. Financial planning cannot be overlooked, and therefore, we will elucidate the CBG plant cost and explore the government incentives available, optimizing your fiscal strategy. Our goal is to ensure that from concept to reality, your journey to inaugurate a Compressed Biogas endeavor is informed, methodically planned, and primed for success.

strategy. Our goal is to ensure that from concept to reality, your journey to inaugurate a Compressed Biogas endeavor is informed, methodically planned, and primed for success.

Fostering a sustainable energy future, we move forward with this discourse by dissecting each element of a CBG Plant Setup, equipping you with essential knowledge on scaling, future expansion, and the CBG capital requirement. Acknowledging the operational challenge, we'll illustrate best practices for ongoing operations and maintenance. Moreover, the final cog in the wheel—marketing and selling CBG—will not be overlooked, ensuring your venture's profitability and long-term viability. Join us as we embark on this detailed journey, transforming the blueprint of your CBG plant into a tangible asset.

Understanding Compressed Biogas (CBG)

Venturing deeper into our exploratory narrative, it is imperative to shed light upon the cornerstone of our discourse—Compressed Biogas, or CBG. As practitioners in this burgeoning arena, we view CBG as a game-changer in the clean energy sector. Often known as biomethane, CBG is procured through the anaerobic digestion of organic matter, rendering it a formidable enemy of greenhouse gas emissions. This sustainable energy alternative is witnessing increasing valorization as it paves the way for cleaner transportation, power generation, and heating solutions.

In our quest to harness CBG's potential, we acknowledge the technological kinship it shares with natural gas; through compression, CBG attains a form akin to natural gas, ensuring ease of transport and storage. Weighing in on its versatile applications, we recognize that CBG can seamlessly replace Compressed Natural Gas (CNG) in vehicles, demonstrating equivalency not only in chemical composition but also in caloric prowess. To encapsulate the circular economic growth envisioned within our Gobar Gas Plant initiatives, we address the valuable by-products—solid residues transform into nutrient-rich bio-manure that champions crop growth and minimizes the demand for chemical fertilizers, while the CO2 captured during purification stages maneuvers into profitable avenues such as food preservation and fire suppression.

Our commitment goes beyond mere production; we extend our visions to the pragmatic facets of the CBG Plant Setup Process. Aligning with India’s SATAT initiative, we seek to bolster green transportation by integrating CBG into the retail outlet networks managed by Oil Marketing Companies (OMCs), thereby weaving it into the fabric of mainstream fuel consumption. We leave no stone unturned in presenting CBG Plant Setup Requirements, encompassing savvy financial planning inclusive of the CBG Plant Cost and capital requisites. As stewards of innovation, we are inclined to guide future pioneers in acquiring the necessary License for CBG Plant operations, ensuring compliance and facilitating access to governmental endorsements such as the MNRE subsidy and Priority Sector Lending.

Such is the blueprint of a sustainable path we aid to construct, marked by the cardinal checkpoints of seamless integration, economic viability, and environmental stewardship. We urge prospective stakeholders to explore the possibility of contributing to a cleaner ecosystem through committed involvement in the CBG Plant Setup process. Together, we embark on a journey that promises a greener tomorrow through the valorization of an incredible resource—Compressed Biogas.

Feasibility Study and Site Selection

As we progress on the journey to establishing our own Compressed Biogas (CBG) venture, one of the most pivotal stages is the comprehensive feasibility study accompanied by methodical site selection. A well-conducted study determines the viability of our CBG plans and ensures that our resources are invested prudently. Herein, we scrutinize various aspects critical to the project's success:

- Project Description: We begin with a meticulous assessment of the CBG Plant Setup, detailing the scope, scale, and operations intended for our Gobar Gas Plant. This includes envisaging the technology to be utilized, gauging the production capacity, and anticipating the integration within the existing energy infrastructure.

- Technical Feasibility: Our focus then shifts to ascertain whether the technology and design envisaged for our CBG Plant Setup Process are compatible with the chosen location. Furthermore, we evaluate the availability of sufficient feedstock supply within the locality to sustain the plant operations.

- Economic Feasibility: A pivotal aspect in our agenda is the financial analysis, where tools like net present value, internal rate of return, and payback period calculations come into play. We must ensure that the projected CBG Plant Cost aligns with our CBG Capital Requirement and financial backdrop. Deploying financial models, we predict the costs and revenues, bearing in mind the government incentives that potentially lighten our fiscal commitments.

- Environmental and Social Feasibility: It is our duty to ascertain the environmental implications of establishing the CBG facility. This includes the analysis of potential emissions, waste by-products, and the overall carbon footprint. Social feasibility is equally paramount - gauging local community consensus and evaluating the ripple effect of our establishment on local employment and economic growth.

- Legal Feasibility: In the intricate reconnaissance of legal landscapes, we assiduously chart our pathway to obtaining the necessary License for CBG Plant. Here, adherence to the regulatory framework and securing approvals from relevant authorities remains a top priority.

- Site Selection: Our sights are set on selecting a site that not only facilitates logistical efficiency but also caters to the technological demands of our operations. Crucial factors aiding our decision-making include proximity to feedstock sources, access to distribution networks, and compliance with zoning and land use regulations.

Our due diligence encompasses international case studies such as the Gobardhan Bio-CNG Plant project in Indore, India, which serves as a beacon, illuminating the path with best practices and benchmarks for aspiring CBG plant projects.

This diligent groundwork lays the foundation for our subsequent endeavors. By meticulously examining each one of these facets, we are well-equipped to make informed decisions, propelling us further in the CBG Plant Setup Process, and closer to realizing the vision of operationalizing our own renewable energy powerhouse. With every step taken in this detailed evaluative process, we reaffirm our commitment to sustainability, economic viability, and community advancement.

Obtaining Necessary Permits and Approvals

Venturing into the particulars of establishing a CBG Gobar Gas Plant, the intricate web of permits and approvals comes to the forefront. As we navigate this procedural labyrinth, our due diligence begins with securing multiple documents and clearances, a critical leap forward in our CBG Plant Setup Process. Embarking on this administrative journey, we comprehend the weight of each authorization, cognizant that each document charts us closer to our renewable energy aspirations.

The checklist of permits necessary to set up a Compressed Biogas plant is extensive and encompasses:

- Local Authority Site Clearance: This is crucial as it forms the bedrock of our establishment, sanctioning the utilization of the chosen locale for our CBG operations.

- Environmental Clearance: Compliance with environmental regulations is not merely a formality but a testament to our commitment to sustainability.

- CTE and CTO: Standing for Consent to Establish and Consent to Operate, respectively, these validate our plant’s functionality within legal environmental frameworks.

- Land Documentation: Clear and undisputed land documents to affirm our right over the intended site.

- District Level Site Selection Committee Permissions: A vital regional endorsement to fortify our groundwork.

The continuum of authorizations doesn't end there — our engagement with statutory requirements deepens. Our responsibility is to procure the following:

- Local Panchayat Approval

- Plan Approval by IOF

- Safety & Health Standards Clearances

- PESO and BDO Licenses

- For bio-CNG plants, a Manufacturing License specific to biofertilizer production is rendered non-negotiable, ensuring we can distribute biofertilizers derived as by-products.

- GMP Certification is pivotal, instilling trust in our biofertilizers' safety and consistency.

- Trade License, Import-Export License, and pertinent Tax Registrations buttress our manufacturing and commercial operations.

Venturing beyond the establishment phase, the financial outlay earmarked for our CBG Plant Cost between Rs. 10,000 to Rs. 25 lakhs demands a close evaluation of revenue potential and economic incentives. With eyes set firmly on both current and future horizons, we remain vigilant to evolving regulations, never losing sight that our operational sanctity hinges on constant conformity with these dynamics.

Illustrating the practical realm of our conversation, let’s pivot to the Coimbatore Waste to Compressed Biogas Project—an exemplar of concerted endeavors in waste management. Amidst the pursuit of approvals from Coimbatore City Municipal Corporation and Tamil Nadu Urban Infrastructure Services Limited, the project is poised to reduce GHG emissions by a staggering 25,183 tCO2e per year over a 15-year span, exhibiting adherence to SDGs 7, 11, 12, and 13 while capturing the socio-economic essence of our CBG plant setup initiative in spirit and practice.

Our mission to solidify the structural backbone of our CBG enterprise is steadfast. Walking through the corridors of statutory compliance, we reaffirm our pledge to the environment, fortifying the project against operational, policy, and commercial risks. Endowed with the support from the SATAT Initiative and the prospect of ITMO financing, the ardor to thrive within the realm of Compressed Biogas emboldens us. With meticulous attention to the complexities of permits and approvals, our journey in the CBG Plant Setup realm assumes a posture of assured progression, underscoring the pertinence of strategic, legal, and environmental soundness in realizing the dream of an indigenous CBG Gobar Gas Plant.

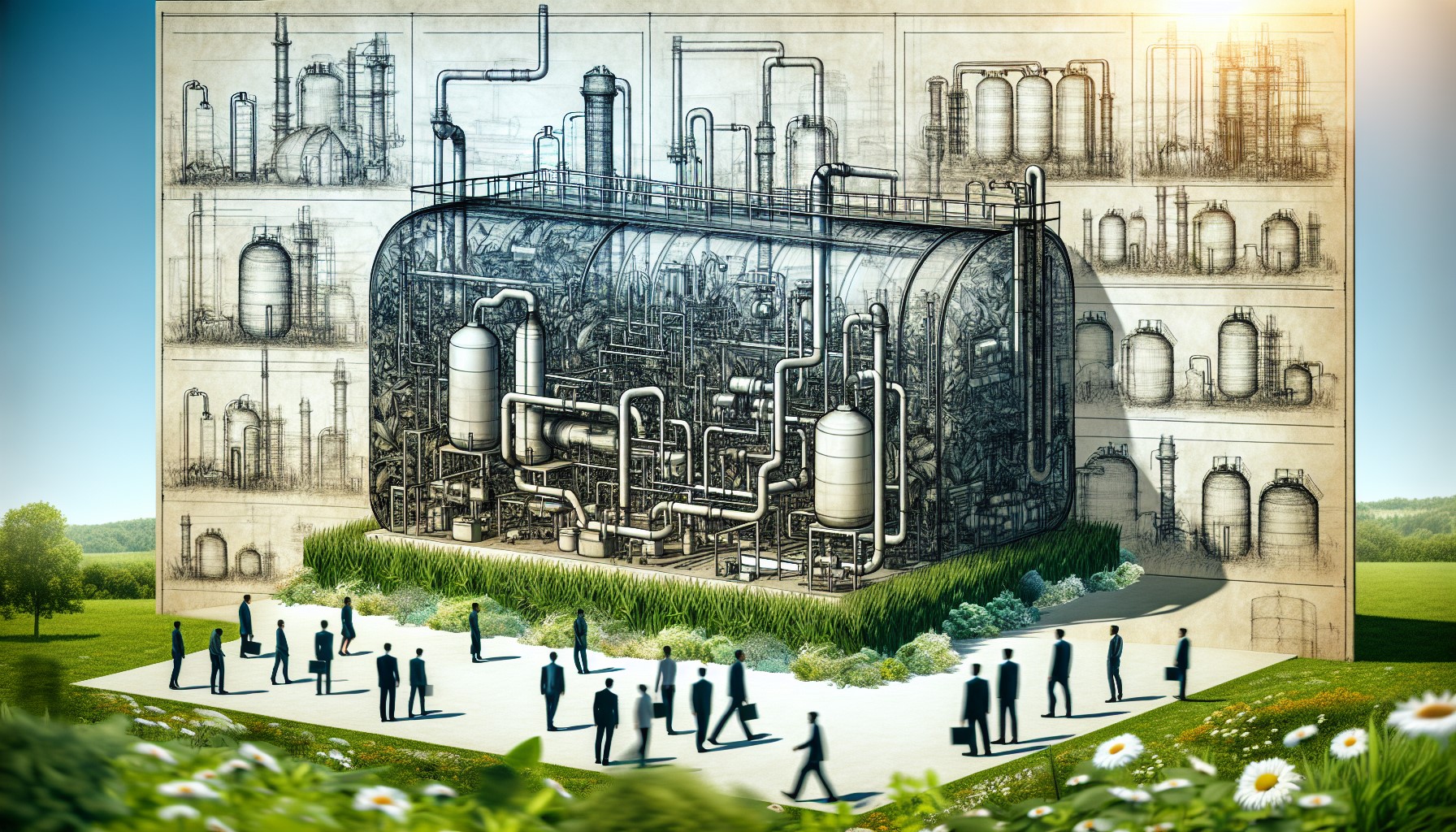

Design and Construction of the CBG Plant

The vision of establishing a Compressed Biogas plant shifts from conceptualization to tangible action during the design and construction phase—the stage where precision engineering and strategic planning intertwine to birth a fully functional, productive facility. Drawing from our comprehensive knowledge of the CBG Plant Setup Process, we prioritize meticulous design, which ensures optimal biogas production and effective management of organic waste feedstocks.

Blueprints and Architectural Design:

- Our approach begins with drafting detailed schematics tailored to the specific technological requirements and processing capacity of the CBG facility. Ignited by empirical data, we architect blueprints that reflect our intended operational scale, keeping in mind the nuances of anaerobic digestion processes.

- The blueprint envisions the plant's fundamental components, including the anaerobic digester, gas collection and storage systems, and purification units that facilitate the conversion of raw biogas into quality CBG.

- We emphasize a layout that facilitates seamless flow and integration between different operational zones, from feedstock delivery to digestate processing, adhering to stringent safety standards and efficiency protocols.

Construction Methodology:

- As we embark on the construction, we employ proficient techniques aligned with both environmental stipulations and our steadfast dedication to resource efficiency. Our operational toolkit features equipment like heat exchangers in the digester to maintain the ideal temperature for microorganism activity, coupled with advanced purifying chambers that meticulously extract CO2 and H2S, ensuring a superior grade of CBG output.

- With an appreciation for localized ingenuity, we cite an exemplar from Nigeria, where a CBG plant was constructed utilizing accessible materials, signaling how adaptive models can be replicated effectively in diverse contexts. This example is reflective of our ethos: leveraging local resources to optimize the CBG Plant Setup Process while mitigating the expenditure tied to our CBG Plant Cost.

Implementation Factors:We consider several key factors during the construction phase: - Tank Size and Scalability: Determined by daily waste collection volumes and projected growth, we establish an anaerobic digestion tank's dimensions that can accommodate the quantity of feedstock while allowing for scalable enhancements.

- Energy Utilization: Our system design incorporates the use of CBG to power a CHP plant or as a renewable transport fuel, maximizing the utility of generated biogas.

- Material Selection: Prioritizing sustainability, we use durable, locally sourced materials for construction, reflecting our commitment to cost-efficiency and environmental stewardship.

We proceed with construction in adherence to state-of-the-art construction practices and the highest engineering standards, always considering our CBG Capital Requirement and operational efficiencies. Regular monitoring and rigorous assessment mechanisms integrate seamlessly into our operations, contributing to a system where safety and performance coexist harmoniously.

Navigating through the CBG Plant Setup Process with precision and professionalism, we lay the foundation of a plant not only as a bastion of renewable energy but also as a symbol of sustainable innovation and meticulous craftsmanship. With each step, we cement our standing as frontrunners in the Compressed Biogas domain, guided by a spirit of ingenuity and a commitment to deliver results that resonate with our core values of sustainability and excellence.

Feedstock Supply and Management

Embarking on the intricate CBG Plant Setup Process, we pivot to a critical component that fuels the very heart of a Compressed Biogas plant: the feedstock supply and its adept management. An uninterrupted and qualitatively standardized feedstock is imperative in maintaining the seamless operation of a CBG facility. Acknowledging this, we meticulously strategize our feedstock procurement and handling to ensure that the operation of our Gobar Gas Plant remains unaffected by fluctuations in supply or quality.

As we navigate through these complexities, we align our practices with the following measures:

- Diverse Feedstock Sources: We conscientiously select varied sources of biomass such as agricultural waste, livestock manure, municipal solid waste (MSW), and press mud. Diversification is key to circumventing potential shortages and achieving a reliable stream of raw material.

- Quality Assurance: The establishment of stringent quality protocols is non-negotiable. It ensures that the feedstock adheres to the prescribed quality benchmark, which translates to higher yields of biogas and, consequently, CBG. The Indian Council of Agricultural Research (ICAR) plays an essential role in setting these quality standards, and we are proactive in adhering to their guidelines.

- Strategic Sourcing and Contracts: To overcome cost volatility, we forge long-term offtake agreements with local agricultural outfits and waste management entities. These partnerships lay the groundwork for a symbiotic relationship that not only secures minimum quality but also fosters community involvement.

Sustainability runs as a common thread through our operations, and in line with the government's SATAT scheme and our mission to reduce crude oil imports, our initiative feeds into the larger narrative of India’s energy security. Our Gobar Gas Plant meticulously integrates the following operational pillars:

- Efficient Collection and Storage Systems: We employ a highly efficient logistics network for the collection and transportation of feedstock to our plant. The aim is to minimize the time from waste generation to the anaerobic digestion process, thus enhancing overall efficiency.

- Fortifying Soil Health with FOM: The digestate leftover from the biogas production, known as Fertilizer Organic Manure (FOM), is an excellent soil additive that helps replenish low Soil Organic Carbon (SOC) levels. We distribute FOM, urging the government to extend Market Development Assistance (MDA) in support of this eco-friendly byproduct until it reaches market parity.

In tandem with operational excellence, we contemplate the economics within the CBG Plant Cost framework. It’s imperative to factor in the incentives and financial assistance provided by the Indian government under various schemes tailored for the CBG sector, effectively reducing our CBG Capital Requirement and accelerating our venture. Whether it's garnering support through Priority Sector Lending or leveraging subsidies and grants, we are keenly aware of the need to optimize financial channels to maintain the project's feasibility and profitability.

Ultimately, diligent feedstock management is not only a cornerstone in our License for CBG Plant but also a testament to our commitment to sustainability and energy independence. By embracing diversity in sources, ensuring quality, forging strategic partnerships, and prudently managing finances, we leverage the vast potential of Compressed Biogas, aligning with the national narrative of cleantech innovation. With our strategies firmly in place, we advance toward a resilient and lucrative CBG ecosystem.

Financial Considerations and Government Incentives

Delving into the fiscal realm of establishing a Compressed Biogas (CBG) plant, we ardently scrutinize the financial considerations intrinsic to actualizing our venture. Unveiling the facets of government incentives further cements our strategic foundation, providing fiscal footholds key to the sustenance and growth of our CBG endeavor.

In the fiscal fabric of our CBG Plant Setup, government incentives gleam as significant enablers. The Indian government's investment of Rs. 858 crores, including Rs. 100 Crore for the Biogas Programme under Phase-I from 2021-2026, reflects the commitment towards the proliferation of small to medium-sized CBG plants. These envisioned installations not only promise organic enriched Bio-manure for farming communities but also align seamlessly with our aspirations of bolstering green energy infrastructures. I am keen on optimizing such incentives as they lay a robust financial groundwork for our Gobar Gas Plant.

Central Financial Assistance (CFA) emerges as a cornerstone within this financial structure. Designed meticulously, the CFA supports CBG plants ranging from 1 to 25 cubic meters of biogas per day. An augmented CFA applies for initiatives in Hilly/NER States, Island territories, and for those under the banner of Scheduled Castes (SC)/Scheduled Tribes (ST) categories. This tiered support is pivotal in our financial planning, easing the CBG Capital Requirement burden. Our eligibility under NNBOMP, contingent upon land/space availability, feedstock resources, regular water supply, and investment capacity, fosters a well-sustained setup process.

Leveraging the Sustainable Alternative Towards Affordable Transportation (SATAT) initiated by the Ministry of Petroleum and Natural Gas since October 1, 2018, aims to weave an ecosystem for CBG production and use. We witness and partake in this surge toward green fuel, wherein Oil and Gas Marketing Companies invite Expressions of Interest to procure CBG. This inclusion guarantees us a stable off-take of CBG at an assured price and fashions financial avenues such as Priority Sector Lending for our Gobar Gas Plant, reducing our CBG Plant Cost.

Furthermore, let us illuminate the financial incentives tailored to our operational scale:

- For small biogas plants, additional fixed subsidies apply if associated with a sanitary toilet or MNRE-approved slurry filter unit, enhancing the fiscal feasibility of CBG Plant Setup.

- A Turn-Key Job Fee facilitates construction, supervision, and commissioning, coupled with a 5-year O&M warranty, ensuring operability without additional financial constraint.

- A monetary incentive of ₹10,000/- fortifies fossil fuel & electricity conservation through Biogas-based Generator sets or Pumping systems, ideally fitting small farm needs.

- The intricacies of financial aid extend to medium-sized plants (above 25 M3 to 2500 M3), with an additional 20% CFA earmarked for select demographics.

Our proposal submission weaves through the MNRE biogas web portal, encapsulating our CBG Plant Setup Requirements thoroughly and securing appropriate funds with immediacy. We regard the SATAT initiative as a testament to our government's mission, mediating fiscal support and spurring CBG plant propagation. Our collaboration with multilateral financial institutions stimulates credit accessibility, offering robust financing options to CBG developers.

Through the Union CBG scheme, partial financing facilitates our venture under a single banking arrangement, enhancing our Gobar Gas Plant's viability. Loans, capped at 75% of project cost, merge with government assistance, wherein a CFA of Rs. 4 crores per 4,800kg of daily CBG production becomes available, with a ceiling of Rs.10 crore per project.

Consolidating our fiscal strategy, we adhere to financial mechanisms integral to the CBG Plant Setup Process:

- Project Inclusion: Under the Agriculture Infrastructure Fund, our plant qualifies as a community farming asset, reinforcing our financial stake.

- Loan Disbursement: Adherence to disbursement protocols assures transparent transactions, with term loans coupled with margins directed through NEFT/RTGS.

- Credit Guarantee: Loans under this scheme gain coverage, nurturing borrower confidence through the Credit Guarantee Trust for Micro & Small Enterprises.

Our visionary stride towards establishing a Compressed Biogas plant is grounded in a holistic financial stratagem, utilizing incentives and fostering partnerships that ensure the fruition of a sustainable, prosperous, and future-embracing CBG landscape. As zealots of renewable energy transition, our comprehension of the financial matrix — from Central Financial Assistance to leveraging SATAT-driven pathways — compels us to forge ahead with unwavering tenacity. Our mantra is clear; sculpt a future where CBG emerges as a linchpin of the green energy escalate, with our Gobar Gas Plant as its steadfast proponent.

Scaling and Future Expansion

As we chart the trajectory of scaling and future expansion within the Compressed Biogas (CBG) landscape, it is heartening to witness industry giants such as Adani TotalEnergies and Reliance Industries leading the way. Their ambitious goals not only inspire our own plans but also lay down a proven roadmap for scaling operations effectively.

- Blueprint for Expansion: Our strategic eye is drawn to Adani TotalEnergies' initiative of establishing five units across India, a clear indicator of the importance of geographical diversification in scaling. Mimicking such a model, we, too, aim for strategic placement of multiple CBG plants that cater to various regions, ensuring a consistent and expanding presence in the bioenergy sector.

- Rapid Scaling: The remarkable feat by Reliance Industries, commissioning their first commercial CBG plant in Uttar Pradesh in a record time, serves as a benchmark for our own CBG Plant Setup Process. Their robust framework enables the replication of a successful model across multiple sites, a tactic we intend to emulate to scale our operations up to 25 plants, ensuring rapid and efficient expansion within the domestic CBG market.

The quintessential element in scaling is a steadfast commitment to sustainable practices, as seen in the path Reliance Industries has embarked upon with their 100 planned CBG plants. Such establishments are poised to make substantial environmental impacts by consuming millions of tonnes of agro-residue, reducing carbon emissions, and producing significant quantities of organic manure. We incorporate similar environmental considerations in scaling our CBG Plant Setup, earmarking us as stewards of both economic growth and ecological welfare.

In tightening our focus on the CBG Plant Setup Requirements for scaling, several factors emerge as pivotal:

- Optimizing Capacity Utilization: With over 90% of operational CBG plants running below intended capacity, we place a heightened focus on pre-planning, skilled personnel acquisition, and a robust understanding of feedstock supply chains. Ensuring that our plants operate at full capability is crucial to our expansion strategy.

- Leverage Government Initiatives: Our gaze is locked on the Indian government's initiatives, such as the SATAT scheme aimed at establishing 5,000 CBG plants nationwide. We strategize to align our expansion plans with national goals, optimizing the opportunity to utilize government incentives and propel our growth trajectory.

- Innovative Feedstock Management: Progressive use of second-generation feedstocks, previously less utilized, forms an integral part of our scaling strategy. This not only diversifies our raw material base but also meets the growing demand for bio-CNG in the transportation sector, bridging the gap between production capacity and market needs.

We are cognizant of the fact that CBG is earmarked as the fuel of the future, with potential to reduce the nation’s natural gas import costs. Accelerating expansion in anticipation of this demand, we lay the groundwork for broadening our reach to a larger customer base, thus solidifying CBG's position as a viable and preferable energy alternative. Our expansion is more than numeric growth; it's the manifestation of India's energy paradigm shift, contributing to the projected $2.5 billion CBG market by 2030.

By integrating these elements into our expansionary vision, we contribute not only to the proliferation of the CBG market but also to the nation's overarching goal of sustainability and self-sufficiency. Our resolve to optimize every facet of our CBG Plant Setup Process, from securing the License for CBG Plant to the financial outlay focusing on CBG Plant Cost, is unyielding, ensuring that our steps towards scaling and expansion resonate with precision, effectiveness, and environmental integrity.

Operations and Maintenance

Stepping into the practical arena of our Compressed Biogas (CBG) initiative, we delve into the aspects of Operations and Maintenance, the backbone of plant longevity and efficiency. Our meticulous approach towards operating and maintaining our CBG facility ensures that we adhere to the highest standards of quality, safety, and environmental stewardship.

In our commitment to operational excellence, here's how we embody the best practices in operation and maintenance of our Gobar Gas Plant:

Monitoring Key Parameters:

- Systematic monitoring of temperature, pH, and gas composition within the anaerobic digesters is fundamental to optimize the microorganisms' activity and maximize biogas production.

- Maintaining the right pressure and gas flow ensures the integrity of the CBG Plant Setup, with regular checks to prevent leaks and pressure drops that could result in operational inefficiencies.

Anaerobic Digester Management:

- Our anaerobic digester is the heart of the CBG Plant Setup, and we ensure its functionality through rigorous inspection and cleaning. This mitigates the risk of blockages and sustains optimal biogas production.

- Timely replacement of parts susceptible to wear and tear, such as seals and mixing equipment, averts unexpected downtimes.

Purification System Upkeep:

- The purification system's role in refining biogas to high-quality CBG mandates us to be diligent. We employ cutting-edge technologies to scrub impurities such as H2S, CO2, and water vapor from the biogas, securing a premium product fit for the market.

- Preventive maintenance schedules for these purification units are strictly followed, vouchsafing the quality of CBG at all times.

In championing a culture of safety first, we unfailingly enact the following measures:

- Gas Detection and Emergency Systems: Updated gas detection systems and emergency shutdown mechanisms are installed at vantage points, fostering a safe operational environment.

- Fire Suppression and PPE: Our Gobar Gas Plant is equipped with state-of-the-art fire suppression equipment, and we ensure that all our personnel are adept in using personal protective equipment (PPE), safeguarding human well-being.

Given the multifaceted nature of our venture, managing the byproduct of anaerobic digestion—a nutrient-rich digestate—is tackled ingeniously, recognizing its potential as a natural fertilizer. Here, we intersect with the circular economy, extending the utility of the CBG Plant Setup beyond energy to agronomical benefit.

Our adherence to the imperative spectrum of regulations mirrors our brand ethos; we meticulously document every operational facet as mandated, be it environmental clearance, health & safety licenses, or securing the necessary License for CBG Plant. These documents, integral to the compliance framework, enable us to navigate the operational landscape responsibly and transparently.

Financial foresight is interwoven into the maintenance strategy, determining our CBG Plant Cost and influencing our CBG Capital Requirement. Our protocols contemplate the economic angle of operations and maintenance, often a determiner of scalability and future expansion capability within the CBG sector.

As we conduct our operations, we remain acutely aware that each facet, from process control to system maintenance, challenges our competency and our collective ambition to fortify the Compressed Biogas narrative. Our resolve is steadfast in upholding high operational standards, as we bear the responsibility to not only meet but continually exceed the benchmarks we set in the CBG Plant Setup Process.

Marketing and Selling CBG

Transitioning from the operational aspects of running a Compressed Biogas (CBG) plant, we pivot to the pivotal stage of marketing and selling the green fuel we produce. It is a step that demands equal measures of strategic planning and shrewd execution to ensure the growth of the industry, and our precise efforts in developing effective distribution channels aim to maximize the utility of our CBG product. With the government's backing through the SATAT scheme, we are poised to capture a significant market share, adhering to our mission to make CBG a mainstream alternative to fossil fuels.

Creating Marketplace Visibility:

- We initiate by conducting awareness campaigns, illustrating the numerous benefits of CBG over conventional fossil fuels, emphasizing its eco-friendly attributes and cost-effectiveness.

- Our marketing strategy intertwines with sales efforts, presenting CBG as the optimal solution across mobility, industries, and commercial sectors. Prospective customers identify with our brand's commitment to sustainability, strengthening our position within the marketplace.

- Strategic Sales Channels:

- Considering the unique nature of the CBG market, direct sales are a cardinal aspect of our approach. We engage directly with end-users through workshops and seminars, fostering lasting customer relationships and understanding their nuanced requirements. This direct line of interaction serves as a feedback loop, polishing our product offering.

- To amplify our reach, we solidify partnerships with Government entities under the Oil Ministry's recommendation to propose CBG blending mandates in all City Gas Distribution (CGD) networks, which market Compressed Natural Gas (CNG) and Piped Natural Gas (PNG).

Navigating Financial Challenges:

- Our thorough grasp of the market acknowledges the hurdles such as intermittent raw material availability and supply chain unpredictability. Nevertheless, we counter these with strategized storage and transportation solutions. Moreover, we are proactive in monitoring our actual off-take based on market response, slowly increasing our supply in alignment with growth trends.

Leveraging Transparent Trading Platforms:

- We keep a watchful eye on the CBG Certification Scheme's framework to utilize a transparent trading platform regulated under the Petroleum and Natural Gas Regulatory Board (PNGRB). This system, along with the deployment of accredited verifiers, ensures the accuracy of our CBG's green attribute.

Pricing Strategy:

- Mindful of financial sensibilities, we aim to competitively price our CBG aligning with the Oil Marketing Companies' (OMC) set purchase price, while also factoring in the transportation and storage expenses. Bridging the cost-efficiency with environmental conservation, we project CBG as the lucrative choice for the discerning customer.

Our dedicated approach extends to navigating policy-driven markets, where the National Biofuels Coordination Committee's mandate for gradual CBG blending in the CNG and PNG segments warrants a proactive pivot in our marketing tactics. Embracing this policy trajectory, we enhance our value proposition for CBG, connecting with a wider spectrum of end-users who value the burgeoning green attributes of our product.

Furthermore, we are ardent about exploring futuristic market mechanisms; the prospect of trading CBG’s green attributes creates an additional revenue stream for our venture. Such innovative practices align with our broader objective, propositioning CBG as a sustainable powerhouse within our energy matrix, candidly reflecting our License for CBG Plant.

In conclusion, the marketing and selling of CBG are more than just a business endgame—it's an embodiment of our commitment to the clean energy future. Through diligent efforts in creating market awareness, establishing strategic sales channels, and adapting to the dynamic financial landscapes, our CBG Plant Setup becomes a beacon of change, revolutionizing how energy is viewed and utilized. It is here, in the convergence of insightful marketing and intelligent selling, that our Gobar Gas Plant achieves its true potential, marring efficacy with environmental responsibility, and cementing our leadership within the Compressed Biogas narrative.

Conclusion

In summary, the journey to establishing a Compressed Biogas (CBG) plant is multifaceted, encompassing intricate planning, strategic financial considerations, and steadfast adherence to government regulations and incentives. This article has walked you through the critical steps of the CBG Plant Setup Process, from conducting a detailed feasibility study to designing the plant infrastructure, managing feedstock supply, and navigating the complexities of permits and approvals. Emphasizing the importance of operational efficiency, maintenance protocols, and marketing strategies, we have highlighted the significant potential of CBG to bolster India's commitment to sustainable energy and contribute to national energy security goals.

The broader implications of our discussions signify the burgeoning role of CBG in India's clean energy landscape and its alignment with global sustainability benchmarks. As the nation steers towards the SATAT initiative and biofuels gain prominence, the comprehensive analysis provided herein serves as a robust guide for aspiring CBG plant developers. Your dedication to this endeavour not only promises economic growth but also ensures environmental stewardship, reinforcing our collective pursuit of a greener future.

FAQs

In the quest to deepen understanding and expound on the multifarious aspects of establishing a Compressed Biogas (CBG) plant, we've compiled a roster of frequently asked questions. These inquiries are reflective of the common curiosities and concerns that prospective CBG plant developers like ourselves frequently encounter.

- What exactly is CBG?Compressed Biogas, or CBG, is essentially methane-rich gas yielded from the anaerobic digestion of organic materials, and shares a striking chemical similarity to natural gas. As we fortify our position in this renewable energy sphere, it's heartening to acknowledge CBG as a renewable, sustainable alternative to fossil fuels, providing a cleaner combustion profile and the chance to autonomously manage our own waste materials productively.

- The Feedstock Quandary:We recognize a breadth of organic waste as feedstock for CBG production, embracing everything from agricultural remnants and food scraps to animal dung and municipal sewage. Akin to the feedstock management practices we've adopted in our Gobar Gas Plant, a comprehensive strategy is pivotal to ensure a consistent, year-round supply that fuels CBG production.

- How does CBG measure up against natural gas?Our exploration into CBG Plant Setup highlights the fuel's incredible versatility, as it could seamlessly substitute natural gas for cooking, heating, or electricity generation. Drawing from our Gobar Gas Plant experience, compressed biogas can be a linchpin in decentralized energy networks, bridging the gap in energy access with a reduced ecological footprint.

- Environmental Gifts of CBG:Compressed Biogas possesses the dual advantage of waste management and emission reduction. By diverting organic waste from landfills, we curb methane emissions and offset traditional fossil fuel utilization, a highlight of our CBG Plant Setup Process. Furthermore, the digestate byproduct enriches agricultural land, nurturing the cycle of life that sustains our ecology.

- Scaling the CBG Fortification Wall:We are acutely aware of the challenges in expanding CBG infrastructure—a journey fraught with financial obstacles and the daunting competition of low-cost fossil fuels. Yet, our unwavering resolve, underpinned by governmental incentives and a growing collective consciousness on clean energy, propels us forward. It's imperative that as an industry, we amplify CBG's benefits, streamlining the License for CBG Plant procedures, while also fostering innovation in technology to outpace these barriers.

- Wastewater and Air Quality Synergy:Our Gobar Gas Plant utilizes the organic maundation present in wastewater, which otherwise serves as a pollution source. This synergistic benefit enhances water quality and reflects our commitment to a cleaner biosphere. Additionally, by claiming carbon neutrality, the CBG Plant Setup ensures that our carbon ledger remains balanced, testifying to the plant's contribution to a healthier planet.

As we further our comprehension of CBG and its integral role within our energy matrix and sustainability goals, certain aspects like regional biogas potential and production infrastructure development become evident. For instance, Florida's potential for annual biogas yield reveals the significant untapped energy reserves diverse regions hold. Such insights inform our CBG Plant Setup Requirements, allowing us to tailor our facilities to regional strengths and resource availability.

Perhaps amongst the more technical inquiries we address is the role of anaerobic digesters in CBG production—indispensable units that, through carefully controlled conditions, usher organic waste through a metamorphosis into valuable biogas and biofertilizer. Here, too, safety is paramount; our Gobar Gas Plant upholds stringent safety protocols to avoid hazards associated with biogas production.

Underlying every question and answer is the recognition of CBG not just as an energy source but as a catalyst for a greener future—a future where reducing carbon footprints, optimizing resource use, and embracing clean energy transition are paramount. As we look to the horizons of a burgeoning CBG industry, we remain poised to address these questions head-on, championing a sustainable energy movement that benefits us all.